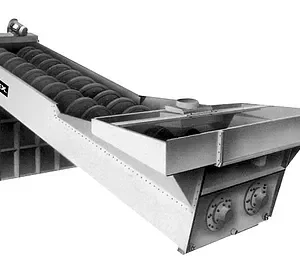

Trakpactor 320 & 320SR

The Powerscreen® Trakpactor 320 is a mid-sized horizontal impact crusher designed to offer operators and contractors both excellent reduction and high consistency of product shape for performance in quarry and recycling applications. With track mobility the plant is capable of working in the

Lesa meiraDescription

The Powerscreen® Trakpactor 320 is a mid-sized horizontal impact crusher designed to offer operators and contractors both excellent reduction and high consistency of product shape for performance in quarry and recycling applications. With track mobility the plant is capable of working in the most demanding environments and features a rapid set-up time, fuel efficient direct drive system and excellent throughput capacity. The Powerscreen® Trakpactor 320SR features a screen and recirculating (SR) conveyor which returns oversized product to the crusher for further reduction. Features Output Potential: up to 320 tph (352 US tph) Suitable for a variety of feed materials including recycling, demolition and quarry applications Bolt in cartridge grizzly – 42mm nominal spacing Load management system to control feeder speed 4 bar rotor and twin apron design Crusher speed variation through user friendly PLC control system Modular conveyor with raise/lower facility to aid clearance of rebar Economical to operate with a highly fuel efficient direct drive system Double deck grizzly feeder with under screen (Trakpactor 320) Double deck 11′ x 5′ post screen (XH320SR) Specification Trakpactor 320 Weight 35,280kg (77,779lbs) Transport width 2.55m (8’4″) Transport length 14.78m (48’6″) Transport height 3.46m (11’4″) Working width 5.61m (18’5″) with side conveyor Working length 14.36m (47’1″) Working height 3.9m (12’10”) Specification Trakpactor 320SR Weight 46,240kg (101,941lbs) (Vibrating grizzly feeder) 48,600kg (107,144lbs) (Pre-screen) Transport width 3.1m (10’2″) Transport length 17.58m (57’8″) Transport height 3.4m (11’2″) Working width 5.82m (19’1″) with side conveyor Working length 17.22m (56’6″)